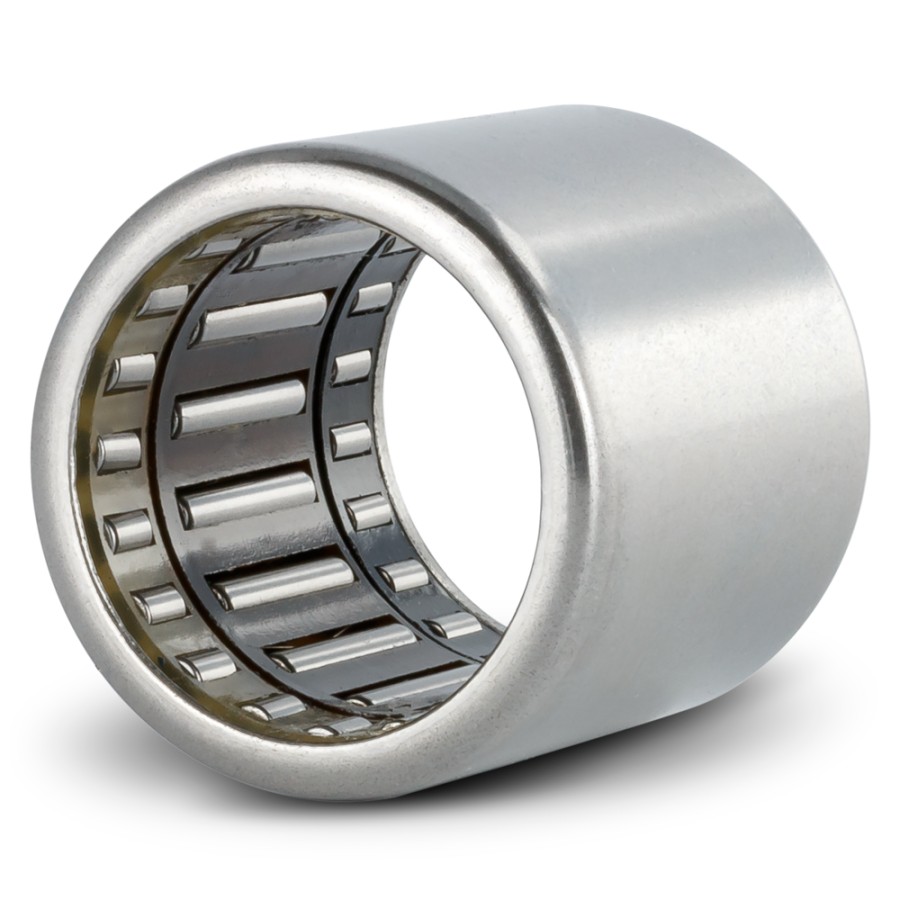

DRAW CUP ROLLER CLUTCHES

Get Fastest Delivery / Get Best In Market Rates / 43+ Years Of Experince

Shree Balaji Export, one of the leading companies providing drawn cups and roller clutches, manufactures one-way clutch solutions for power transmission systems. We are a reputed partner providing products and services to customers in Sri Lanka, South Africa, the UAE, Nigeria, Egypt, Indonesia, Thailand, and Kuwait. Our high-quality drawn cup roller clutches are uniquely designed to apply torque in one direction but free overrunning motion on the other to be a compact and high-performance solution.

Uses of Drawn Cup Roller Clutches

- Overrunning Clutches (Freewheels): These types are applied in both the starter systems of engines and industrial machines. They pass the starting torque and disengage (against their own volition, in the event of overrun) automatically when engine speed exceeds the starter speed.

- Indexing Devices: These clutches are found in printing presses, feeders and packaging machines and are used to give a material a specific amount of rotation (indexing).

- Backstopping (Anti-Reverse) Devices: These are very important in conveyor systems and on large gear drives; they stop the reversal of movement whenever the drive is switched off, and this is to maintain a safe surface and prevent the reversal of material on a sloping surface.

- Two-Speed Gearboxes: These are used in certain types of automatic transmission systems and in specific power tools to switch gears in one direction automatically. The other option is a coast or gear switch.

Features of Drawn Cup Roller Clutch

- Compact Radial Design: As with drawn cup bearings, the thin drawn outer ring reduces the radial space demand, and the clutch can be fitted readily into a wide range of small assemblies.

- High Torque Transmission: The design has ramps or wedges on the outer cup that push the needle rollers against the shaft when rotated in the drive direction, with high transmission capacity in terms of torque, despite their small size.

- Simple, Press-Fit Installation: The outer cup can be drawn to enable parting in the housing bore to clamp the clutch. This makes the assembly process easier and does not require complicated mounting tools.

- High Indexing Accuracy: In indexing, the multiple roller elements and accurate ramp angles achieve high accuracy, which is needed in repetitive manufacturing and printing operations.

Shree Balaji Exports

Shree Balaji Exports