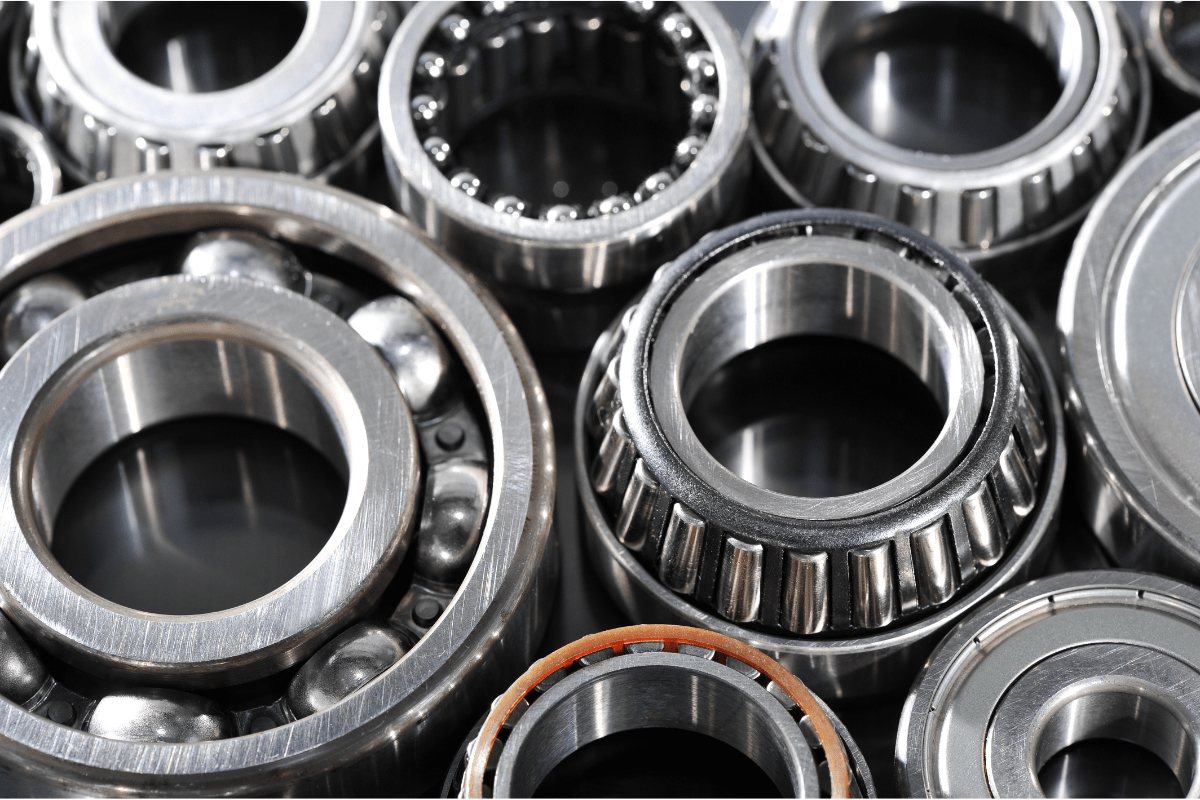

FAG BEARING

Get Fastest Delivery / Get Best In Market Rates / 43+ Years Of Experince

Shree Balaji Export is among the major manufacturers and suppliers of FAG bearings. We also produce quality bearings with numerous industrial uses. We have been a well-known FAG distributor and supply consumers in Sri Lanka, South Africa, UAE, Nigeria, Egypt, Indonesia, Thailand and Kuwait. Our product range covers an immense range of FAG bearings, all of which perform well and have a longer service life in harsh environments.

Key Applications of FAG Bearings

- Automotive Industry: FAG bearings are employed in engines, transmissions and wheel assemblies. They guarantee high levels of performance and safety of their vehicles.

- Industrial Machinery: FAG bearings support heavy-duty equipment such as pumps, motors, and conveyor systems. They are also able to balance heavy weights and precision in every operation.

- Power Generation: FAG bearings power wind turbines and other power-generation equipment. They work well in harsh environments and react fast to achieve maximum productivity.

- Heavy Earthmoving Machinery: FAG bearings are used directly in heavy earthmoving machines in construction and mining, where loads and shocks are very intense. They are incorporated in loaders, excavators, and bulldozers, prompting smooth operation.

Characteristics of FAG Bearings

- Excellent Establishment and Performance: FAG bearings are prepared with extensive care, thereby maintaining low friction and silence. This accuracy provides energy efficiency and less maintenance.

- Improved Strength Level: With the employment of high-density stainless steel and other hardened materials, FAG bearings withstand erosion even in the most aggressive environments. Their strong structure prolongs the life span of the machinery.

- Flexibility: FAG bearings suit all types, sizes and configurations, used in a wide variety of applications, including high-speed movements and heavy load motion or stationary.

- Greater Load Capacity: The engine design of FAG allows its bearings to be exposed to high radial and axial stress, and as such, they are suitable and should be used in stressful and high support cases.

Shree Balaji Exports

Shree Balaji Exports