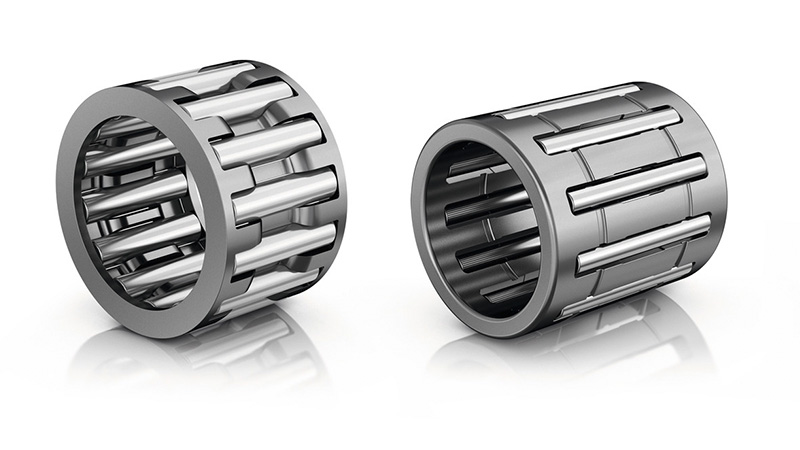

NEEDLE ROLLER & CAGE ASSEMBLIES

Get Fastest Delivery / Get Best In Market Rates / 43+ Years Of Experince

Shree Balaji Export is a major manufacturer and supplier of needle rollers and cage assemblies, and its specialised components offer compact and highly performing bearing components. We are a reliable distributor and serve customers in Sri Lanka, South Africa, the UAE, Nigeria, Egypt, Indonesia, Thailand and Kuwait. Our high-quality assemblies are made explicitly in those systems where space is a costly commodity; they have xenon load capacity within the smallest radial cross-section.

Applications of Needle Roller and Cage Assemblies

- Automotive Transmissions: These are extensively applied to the planetary gears, the layshafts, and reverse idler gears of manual and automatic transmissions. This low radial height is an essential factor in the shrinkage of current gearboxes.

- Universal Joints (U-Joints): These are the centre rolling components in U-joints that support the oscillatory loading and high loads of the driving system in a very enclosed area.

- Two-Stroke Engine Connecting Rods: These assemblies are employed on the crankpin and piston pin in high-performance, compact (such as chain saws and motorcycles) engines, where they are highly loaded and lightweight is required.

- Compressors and Hydraulic Pumps: These components are used in piston pumps and compressor crank mechanisms, where the high loads and high speeds require the radial space to be minimal, which is vital as regards the total size of the pump.

Features of Needle Roller and Cage Assemblies

- Extremely Low Radial Cross-Section: These features have a low radial space requirement because the cage and needle rollers are the only components of the assembly. This permits the inner and outer raceway to be the hardening, ground shaft, and housing bore.

- Size, maximum load capacity: The cage directs many long, thin needle rollers, which give an unusual number of contact lines. This gives the maximum load-carrying capacity of any cross-section.

- High-Speed Capability: The strong cage precisely steers the rollers, reducing friction and eliminating skewing. This enables the assemblies to work more effectively with high rotational speeds, which is required by engine and transmission parts.

- Reduced Housing and Shaft Construction: The construction can do away with the requirement of inner and outer rings (in most arrangements), and machine parts' bearing and ground surfaces (shaft and bore) can be used as the raceways. This eases the overall bearing arrangement and minimises the number of components.

Shree Balaji Exports

Shree Balaji Exports