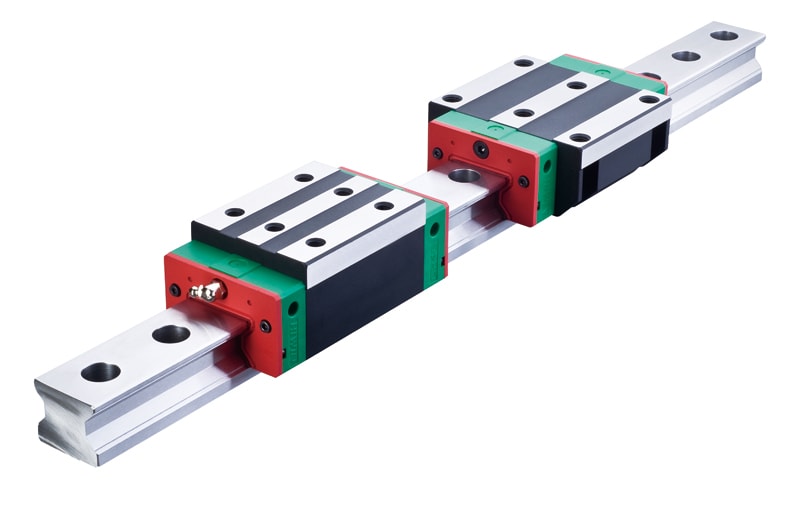

LINEAR GUIDEWAYS

Get Fastest Delivery / Get Best In Market Rates / 43+ Years Of Experince

Shree Balaji Export is one of the dominant suppliers and manufacturers of Linear Guideways in the motion control industry, offering high precision to automated machine work. We are a reputable distributor of Linear Guideways and cater to the needs of our clients in Sri Lanka, South Africa, UAE, Nigeria, Egypt, Indonesia, Thailand and Kuwait. The quality of our linear guideways is designed to carry heavy weights with excellent rigidity and precision, providing smooth and repeatable linear motion.

Major users of Linear Guideways

- CNC Machine Tools: CNC machines have feed axes (X, Y and Z) used in CNC milling machines, lathes and grinders. They support the high rigidity and precision needed to hold the position of tools and achieve the required accuracy in the micro range or less during machining.

- Industrial Robotics: These are required in the linear motion axes of gantry robots and multi-axis assembly machines. They allow movement of objects like welding, pick-and-place or inspection in a fast, precise and repeatable manner.

- Semiconductor Manufacturing: Wafer, tester, and Lithography equipment are used in clean rooms. They have low friction and are highly precise, paramount in moving delicate parts without vibrations.

- Medical and Laboratory Equipment: CT scanners, MRI machines, and automated fluid dispensers. They guarantee the fine, noiseless, and precise control of the enormous gantries and fragile tools.

Features of Linear Guideways

- Large Load Capacity in Every Direction: Modern linear guideways (typically with recirculating ball or roller technology) are engineered to handle loads in all four directions (radial, reverse radial and two lateral) without the need to design machines with sideways forces on all but two.

- Unusual Rigidity and Stiffness: The rigidity is high due to the tight contact between the bearing blocks and the rail, and in many cases, the bearing blocks are already loaded. This reduces under load deflection and vibration, essential in high-precision machining.

- Low Friction and Smooth Movements: Recirculating rolling elements are used to guarantee a low level of friction. This provides very energy-efficient movement, reduces the effect of stick-slip, and makes it operate smoothly even at low speeds.

- High Positioning Accuracy: Linear guideways are precision-ground and machined to narrow tolerances, providing high levels of straightness and parallelism. This directly translates to high positioning and repeatability accuracy of the machine axis.

Shree Balaji Exports

Shree Balaji Exports